Inkjet Printing for Digital Fabrication

Digitization is everywhere, also in printing technology. The trend goes to digital printing technologies like inkjet printing. Imagine you could use your office inkjet printer at home (the one that uses ink cartridges, not laser) for 3D printing of a human organ for biomedical applications! What do you need to change on your office printer to be able to do so? What kinds of inkjet printheads, inks and substrates do you need to use? What else do you have to take care of (temperature control, drying of the ink, electrical control unit)? In other words: How do you apply inkjet printing for digital fabrication?

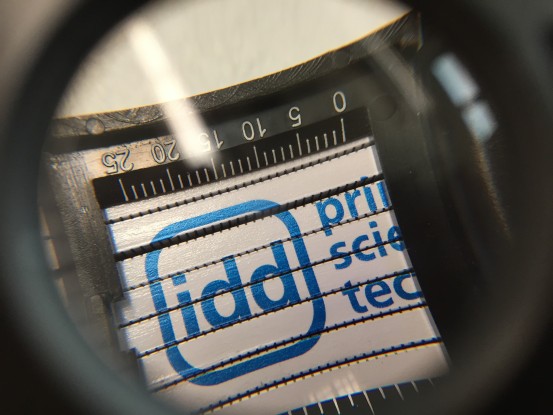

Within the lecture, all of these questions are addressed and discussed. Students are introduced to digital printing techniques and the different principles of inkjet printing (piezo, thermal, drop-on-demand etc.). They learn the theory and models behind inkjet printing: How does an inkjet printhead produce small droplets? What are typical properties of inkjet inks and how can you describe them? The design of typical inkjet printheads is explained. Another topic of the lecture are fluid-substrate interactions: What happens when a droplet hits the substrate e.g. paper? Will the droplet spread on the paper? What does the printed droplet look like when it has dried? With the learned theories, the students will be able to derive simple models for inkjet printing and drop formation. After the lecture, students will know the most important printing parameters and characteristic numbers (Weber number, Ohnesorg number etc.). Another aim of the lecture is to reflect different trends of digital fabrication and to present and discuss possible applications for inkjet printing like biomedical printing, 3D printing and printed electronics (solar cells, OLED-displays etc.).

The lecture is part of the Master „Wahlfächer aus Natur- und Ingenieurwissenschaft“ and will be held in English language.