Because of the advantages and disadvantages of each 3D printing technique, there is also stereolithography and 3D inkjet printing available. Both make it possible to produce high quality surfaces. A dedicated post treatment is necessary for each printing method. But there are less materials available as in fused filament fabrication.

Process data can be generated by designing or 3D scanning of objects. There is computer aided design software and the availability of topological optimization. Furthermore, it is possible to import and edit scanning data. For the 3D scanning method, here are different techniques each with specific advantages and disadvantages.

For students:

The lab and the related infrastructure can be used for student projects or final assignments providing the sufficient knowledge of the related process steps. Please participate in the tutorial. Please find the actual and relevant dates in TUCaN.

The E3D ToolChanger & Motion System is a multi-material FFF printer that features a tool changing system. This allows up to 4 different print heads to be used, for example for four different materials. At the same time, as a modular research platform, this 3D printer offers the possibility to integrate your own tools.

- Build volume 200mm x 300mm x 300mm

- 4x E3D Hemera extruders with E3D v6 hotends

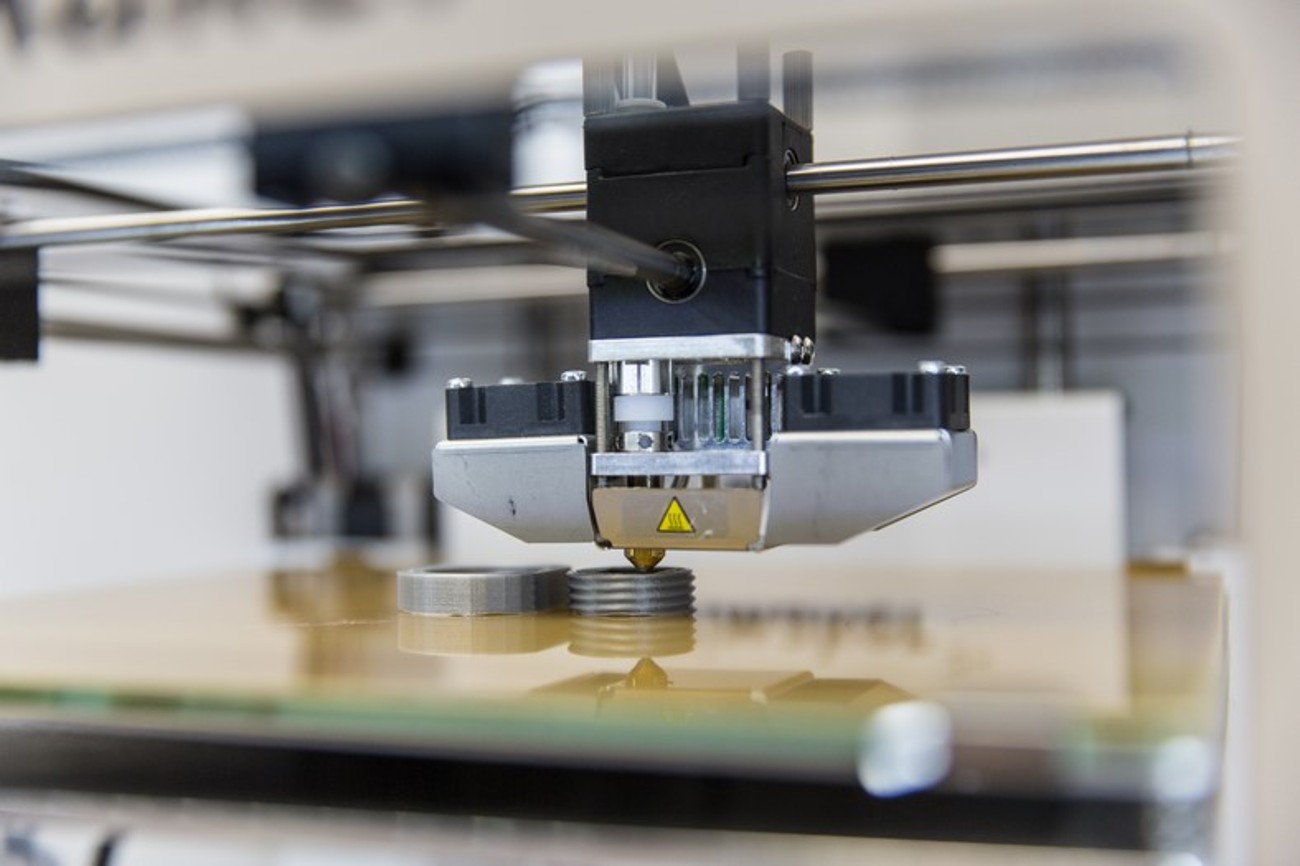

The Ultimaker S5 from Ultimaker B.V. is a Fused Filament Fabrication (FFF) (also known by the brand name Fused Deposition Modeling, FDM) 3D printer. It can process plastic filaments by the use of two print heads layer by layer.

Technical specifications:

- printing volume: 330 mm x 240 mm x 300 mm

- filament diameter: 2.85 mm

- nozzle diameter: 0.25, 0.4 and 0.8 mm

- print head temperature up to 280°C

- heated platform with durable printing plate, temperature up to 140°C

- closed build chamber

- material: ABS, PLA, CPE, PETG, nylon, PVA, and others

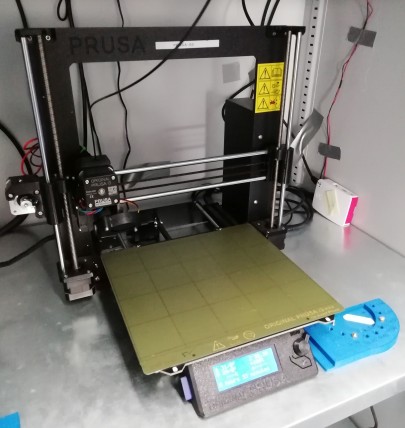

The i3 MK3S from Prusa is a Fused Filament Fabrication (FFF) (also known by the brand name Fused Deposition Modeling, FDM) 3D printer. It can process plastic filaments by the use of one print head layer by layer.

Technical specifications:

- printing volume: 250 mm x 210 mm x 210 mm

- filament diameter: 1.75 mm

- print head: E3D V6

- nozzle diameter: typical 0.4 mm, others possible

- print head temperature up to 300°C

- heated platform with durable printing plate, temperature up to 120°C

- material: ABS, PLA, CPE, PETG, and others

The Modix Big Meter is a Fused Filament Fabrication (FFF) (also known by the brand name Fused Deposition Modeling, FDM) 3D printer, with a very large build volume of 1 m³. It has two print heads with E3D SuperVolcano hotends, a closed housing, high-quality guiding, sensors to detect the end of the filament and automatic bed leveling.

- print volume: 1010 mm x 1010 mm x 1010 mm

- filament diameter: 1.75 mm

- 2 print heads: E3D SuperVolcano

- nozzle diameter: 1.0 mm to 1.4 mm

- printing bed heated up to 120°C

- closed build chamber

- printing materials: ABS, PLA, PETG, PVA, nylon and others

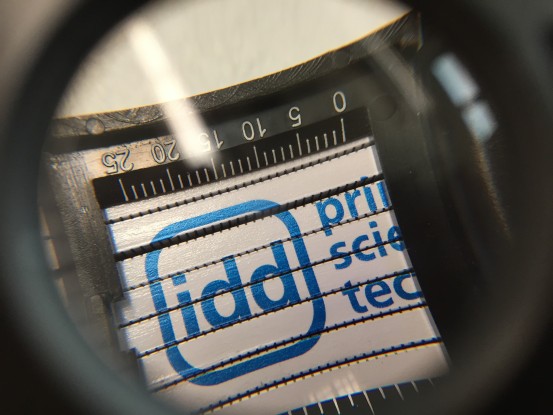

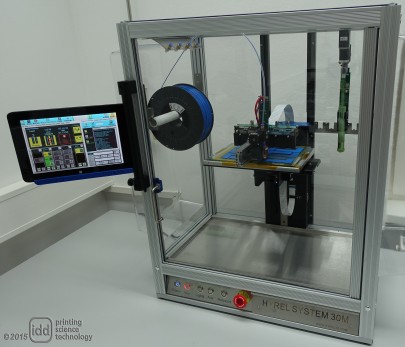

The system 30 from Hyrel is a hybrid 3D printer. In addition to the well-known fused deposition modeling (FDM) it offers printheads for more applications to build 3-dimensional objects. Different types of syringes, some of them are heated, with different nozzle diameters or needles are used as a printing nozzle. In addition, a UV-LED ring for cross-linking immediately after printing and a laser head are available.

- Printable volume: 200 mm x 200 mm x 200 mm

- 4 printheads, which can be used simultaneously

- Printing bed heated

- Positioning accuracy: 0.05 mm in X- and Y-, and 0.02 mm in Z-direction

- Print heads:

- FDM extruders with a maximum of 250°C and 400°C extruder temperature

- Various syringes, partially heated up to 150°C, with different nozzles

- Syringe with UV-LED ring working at 365 nm wavelength

- Printing materials: ABS, PLA, PVA, soluble and meltable plastics, silicone, putty, clay, biomaterials and others

The plastic extruder NEXT 1.0 from the manufacturer 3devo is suitable for the production of round plastic wires (English filament) with a diameter of 0.5 to 3 mm. Thickness control and automatic rewinding enable autonomous operation. Thanks to the four heating zones, plastics can be extruded at a precise temperature control up to an extrusion temperature of up to 430 °C.

Materials: Thermoplastics (e.g. ABS, PLA, PA12, PEEK)

The Mosaic Palette makes it possible to process up to four different filaments with different materials, colors or hardnesses using just one nozzle or extruder on the 3D printer. For this purpose, the individual filaments are cut automatically and software-controlled, welded into a single filament and fed to the 3D printer.

The Mosaic Palette 3 is a device that can be used together with 3D printers and allows multiple filaments to be used simultaneously. By using the Palette 3, 3D printers can create objects with multiple colors or materials. It is possible to use up to 8 different materials in one component.

The X1 Carbon from the manufacturer Bambulab belongs to the latest generation of 3D printers that use the fused filament fabrication process. It is characterised by its many built-in sensors, which allow it to be controlled and monitored remotely. For example, the components can be detected by a built-in lidar scanner during printing and automatically inspected for build errors. In addition, the 3D printer is characterised by a very high build speed and an automated material change system, which allows up to 16 materials or colors to be processed in the same print job.

Technical specifications:

- Printing volume: 256 mm x 256 mm x 256 mm

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Print head temperature up to 300°C

- Heated platform with durable printing plate, temperature up to 110°C

- Closed build chamber

- Maximum speed: 500 mm/s

- Automated material system (currently 4 materials)

- Materials: ABS, PLA, PETG, PC, PA6, PVA, etc.

Stereolithography (SLA, mSLA, DLP)

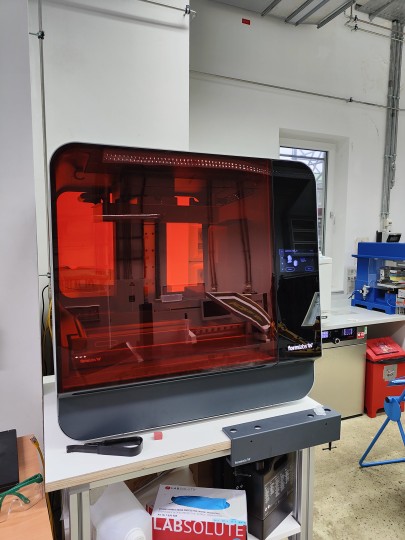

The Form 3L printer from the Formlabs company uses stereolithography, or more precisely low force stereolithography (LFS), to create three-dimensional objects. The process is based on the layer-by-layer photopolymerization of liquid monomers with a UV laser and achieves very high resolutions.

Technical specifications:

- Build volume: 335 × 200 × 300 mm

- Spot size: 85 µm

- Layer height: 25-300 µm

- XY-Resolution:25 µm

The stereolithography 3D printer SL1S Speed of the manufacturer Prusa Research belongs to the newest generation of “Masked Stereolithography” (MSLA) desktop devices. Due to the high light intensity of its UV-LED array and a monochrome LCD masking, layers can be exposed within a few seconds (1.3 – 2.4 s). In addition, the device has a modern layer separation system, in which the FEP film of the VAT base is peeled off during printing by tilting and not peeled off vertically as is usually the case. This allows build speeds of up to 50 mm part height per hour, even for filigree parts.

- Build volume: 127 x 80 x 150 mm

- Pixel resolution (x-y resolution): 50 µm

- Layer thickness: 10 – 100 µm

- Material: photopolymers

- UV LED wavelength: 405 nm

The Inkspire 3D printer from the manufacturer Zortrax belongs to the category of “masked stereolithography” (MSLA) printers. While this process is basically similar to conventional stereolithography machines, a UV LED array is used as a light source in combination with an LCD photo mask to expose the individual layers. This results in the advantage of a significantly reduced layer time, since the entire layer is exposed simultaneously, as well as a simpler construction of the machine with only slightly lower resolutions than in the laser stereolithography process.

- Print volume: 132 mm x 74 mm x 175 mm

- Pixel resolution (x-y resolution): 50 µm

- Layer height: 25-100 µm

- Materials: Photopolymers

- UV LED wavelength: 405 nm

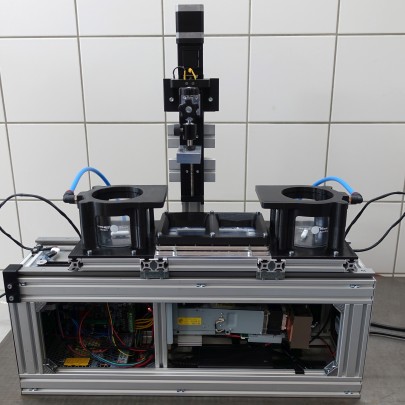

The dual-material DLP printer is an in-house development in cooperation with Prof. Andrieu-Brunsen's research group Smart Membranes. It is based on the DLP process, i.e. it uses micro mirrors to direct the light from an LED into the projection plane. The light then falls through a protective glass and through a fluorinated film at the bottom of a self-designed tub (vat) into the resin. All points to be exposed in one plane are exposed simultaneously.

Components can be built up from one material as in commercial DLP printers. But components can also be built up from two materials supplied by two adjoined vats. If desired, cleaning in solvents (supported by magnetic stirrers) and subsequent dry blowing of the previously printed component can be performed when changing materials. For this purpose, a pre-processing software was developed in Python, in which all relevant printing parameters can be set.

- Projection area: 32.4 x 57.6 mm²

- Component height: max. 50 mm when using two materials, otherwise 100 mm

- Pixel resolution (x-y resolution): 30 µm

- Layer thickness: 20-100 µm

- Exposure power adjustable from 10 to 90 mW/cm², further reducible by grayscales

- UV LED wavelength: 385 nm (changeable to 365 or 405 nm)

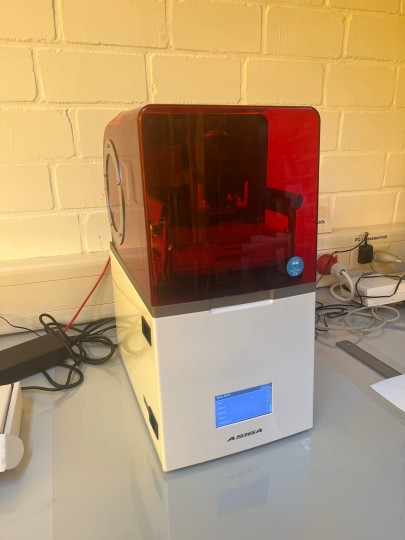

Asiga's MAX X27 is based on Digital Light Processing (DLP) technology. Each layer to be printed is exposed simultaneously, with individually controllable micromirrors responsible for which pixels in each layer are exposed. We have equipped the printer with a new, very smooth, build platform which, in combination with the right resin, enables transparent printing. Therefore it is used in microfluidics as well as for individual cell culture dishes.

- Pixel resolution (xy): 27 µm

- package size: 51.8 x 29.2 x 75 mm

- Layer thickness: 10 – 100 µm

- Material: photopolymers

- UV LED wavelength: 385 nm

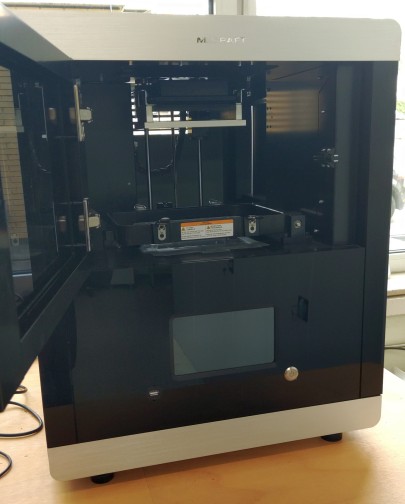

MiiCraft’s Hyper 50 is based on Digital Light Processing (DLP) technology. Each layer to be printed is exposed simultaneously, with individually controllable micromirrors responsible for which pixels in each layer are exposed.

- Pixel resolution (xy): 30 µm

- package size: 57 x 32 x 120 mm

- Layer thickness: 5 – 500 µm

- Material: photopolymers

- UV LED wavelength: 385 nm

Two-Photon Polymerization (2PP)

Nanoscribe’s Photonic GT2 Professional is a state-of-the-art two-photon printer that can print objects with a resolution of less than 1 µm in a very short time. The mechanism of two-photon polymerization can be used to produce extremely delicate objects for applications in microfluidics and nano-optics, as well as for advanced cell culture or artificial blood vessels. In this process, voxels are cured in a resin volume by pulses of a focused laser. By means of a positioning table, objects larger than the working range of the objective can be produced. In this way, structures several millimeters in size can also be produced with a resolution in the nanometer range.

3D scanning systems

The 3D scanner SLS-3 from HP (formerly DAVID Vision Systems) works according to the structured light method. It has an industrial camera and a conventional projector. The scanner generates several scans, which are then merged in the program. A single scan can capture objects ranging from 60mm to 500mm in size. The resolution is 0.05% of the scan. The data can be exported as OBJ, STL and PLY. It is particularly suitable for high-resolution images of small objects including texture.

Technical spezifications:

- resolution: 0,05 % of measured size

- scan area size: 60-500 mm

- data formats: STL, PLY, OBJ

The Scanify from Fuel3D combines the three manufacturer-specific processes Photometric imaging, Geometric imaging and Optical localization. These are essentially based on epipolar geometry, in which the 3D information can be calculated from two 2D image information. The combination of the three methods results in a high-resolution model. The target distance is 400 mm, so that the scanner is well suited for taking pictures of faces with their texture.

Technical specifications:

- data formats: STL, PLY, OBJ

The Sense2 from the manufacturer 3D Systems is a hand-held 3D scanner. The minimum scan volume is 200mmx200mmx200mm and it has an accuracy of approx. 1mm. It is particularly suitable for scanning faces, heads or a complete body with their texture. 3D data is processed directly in the software.

Technical specifications:

- resolution: 1 mm (distance500 mm)

- min measuring volume: 200 mm x 200 mm x 200 mm

- max measuring volume: 1800 mm x 1800 mm x 1800 mm

- data formats: STL, OBJ, PLY, WRL

The 3D scanner SLS-3 from HP (formerly DAVID Vision Systems) works according to the structured light method. It has an industrial camera and a conventional projector. The scanner generates several scans, which are then merged in the program. A single scan can capture objects ranging from 60mm to 500mm in size. The resolution is 0.05% of the scan. The data can be exported as OBJ, STL and PLY. It is particularly suitable for high-resolution images of small objects including texture.

Technical specifications:

- resolution: 224x171 Pixel

- accuracy: 1% measuered value

- rate: < 45 frames/sec

The VR-5200 3D profilometer made by Keyence can capture the surface, shape and contour of components within a very short time using structured light, or more precisely the light section method. Thus, surfaces can be characterized (e.g. roughness according to DIN EN ISO 25178 and DIN EN ISO 4287), measurements on 3D surfaces can be performed and highly precise 3D models can be fed back.

- Measuring area max. 206 mm × 104 mm

- Height resolution: 0.1 µm

- Accuracy in Z: ±2.5 μm

- Accuracy in XY: ±2 μm