Project “ROCKSTAR”

The objective of this project is to develop an innovative and material-saving manufacturing process for the metallization of silicon solar cells.

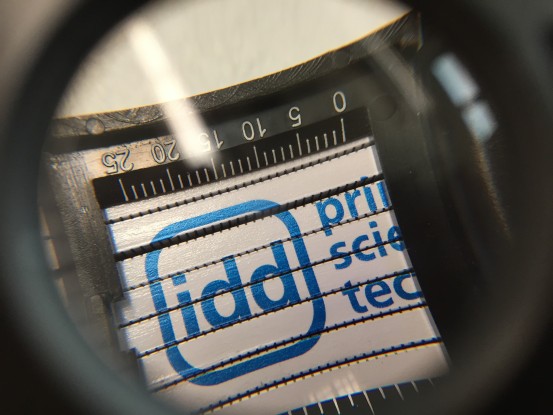

In particular, the front metallization process requires high precision. Extremely fine contact fingers with the width of a human hair must be accurately printed on the surface of ultra-thin silicon wafers without interruption at a high throughput. The aim is to reduce the consumption of expensive silver without a loss in conductivity. This technological challenge places high demands on the automation technology and the materials used.

As a new technical solution for the metallization of solar cells, rotary printing methods such as flexography, rotary screen printing and indirect gravure printing are taken into consideration. Rotary printing processes are mainly used when fine structures have to be transferred at high throughput rates and are therefore highly promising for a new generation of solar cell production lines.