Additively manufactured hot stamping tools

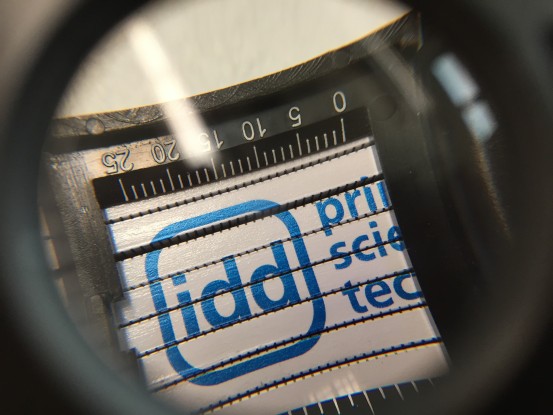

In the R&D project AM-HeiP (additively manufactured hot stamping tools), the IDD is developing a process for the additive manufacture of tools used in the hot foil stamping process in collaboration with Schoder GmbH from Langen, Germany, as part of a grant from the Central Innovation Program for SMEs (ZIM).

Based on a manufacturing process for blind embossing tools also developed at the institute, research is being conducted into increasing the heat resistance and thermal conductivity of tools made from photopolymer resins using the stereolithography process. Additivation and coating of the tools are used. In addition, novel design approaches for composite manufacturing of such tools are being developed. The aim of the project is to increase productivity and flexibility in the design of hot foil stamping tools by designing a digital prepress with additive workflow up to the directly usable stamping tool.