Development of an automated tampon printing process with intelligent process parameter monitoring and control

In the TamPro R&D project, together with Tamponcolor TC-Druckmaschinen GmbH from Neu-Isenburg, IDD is pursuing the development of an automated monitoring and control process for pad printing as part of a grant from the Central Innovation Program for SMEs (ZIM). The focus is on fully automatic control of the viscosity of the printing fluid and the integration of intelligent machine elements.

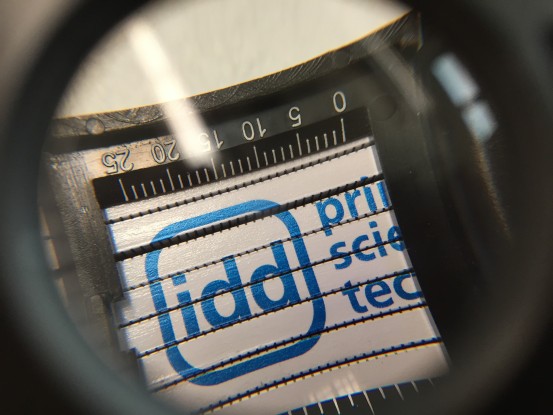

Sensors are implemented for viscosity control, which allow a quantitative estimation of the viscosity or the viscosity change with the help of physical and data-based models. This allows viscosity to be measured without having to implement complex sensor elements for viscosity measurement. In addition, other process parameters relevant for pad printing are to be monitored with the aid of the model-based sensor technology. An important secondary condition is that no additional set-up times are created by the new sensor technology so as not to impair the high flexibility of pad printing. The integration of intelligent machine elements, in turn, aims to automatically set the appropriate parameters for a print job to be carried out.