Biomedical printing technology describes an interdisciplinary field of research at the interface between engineering sciences, biology and medicine. The flexible combination and gentle processing of different technical and biological materials using functional (2D) and multidimensional (3D/4D/xD) printing processes is the central research topic. The aim of the work is to research and develop mechanisms, processes and demonstrators that can make a contribution to regenerative/personalized medicine, to increasing the quality of life in an aging society and to the biologization of technology (Green Deal).

Institute of Printing Science and Technology

BMT

Contact

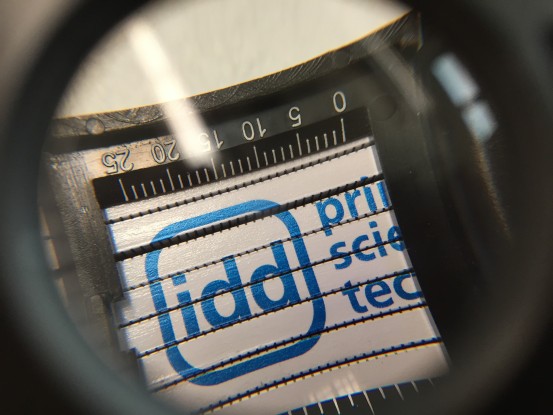

IDD

office@idd.tu-...

work +49 6151 16-22780

fax +49 6151 16-22850

Work

S1|10 203

Magdalenenstr. 2

64289

Darmstadt

We would like to customise the information and usability of this website to your preferences and needs.

To this end, we use so-called cookies. Please choose which cookies you would like to enable when visiting our webpages.

Some of these cookies are required to load and correctly display this website on your device.

These are strictly necessary or essential cookies and cannot be deselected.

The preferences cookie saves your language setting, while the statistics cookie regulates

how the open-source statistical software “Matomo” analyses your visits to and activities on our website.

For more information about cookies we use, please refer to our

privacy policy.