UV Inkjet

Inkjet printing is known for its versatility; its use of only a digital master that can be changed without cost allows small printing runs and even customized products, its non-contact nature makes it suitable for elastic and fragile substrates as well as complex sample geometries and, depending on substrate, ink and printhead, it can print closed and screened layers in an extremely wide thickness range. Monolayers and printed 3D-objects are equally possible.

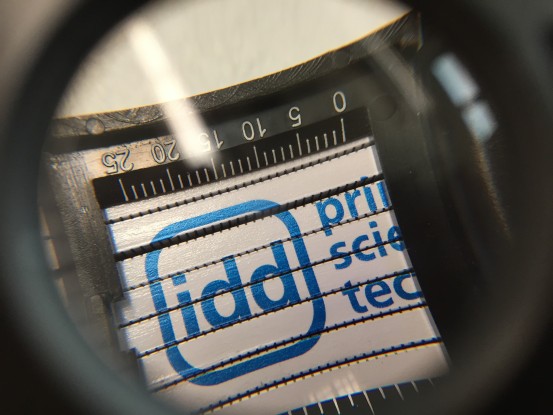

The IDD has partnered with RUCO Druckfarben to run a ZIM project on UV-curable inks for inkjet printing. These are of special interest because they allow a precise control of where and when the ink should harden. It is possible to e.g. control the degree of surface smoothening and even high thicknesses can be cured within a short distance. In addition to this, the use of high-boiling materials reduces the risk of clogged nozzles as well as the amount of vapors and their dangers for health and environment. After curing, the ink is chemically cross-linked, leading to mechanically sound properties, a high tolerance against solvents and a low migration of contaminants.

The project’s goal is the development of LED-curable inks, not only because of LED’s advantages – less harmful to the environment, high longevity, no ozone – but also due to the impending ban on mercury lamps for the printing industry. The inks are optimized for glass and metal substrates, but are expected to be well suited for a host of other substrates.