Research

Our research goal is the development of basic principles that enable the economic use of largely automated printing processes, or in short: Make Printing More Industrial. To this end, we divide our fields of activity into three research groups. Biomedical Printing Technology uses 3D bioprinting and other processes for the production of, for example, organs-on-a-chip, biosensors, meat substitutes and implants. The Industrial Printing group investigates the materials involved in the printing process, models and simulates the sub-processes, and ultimately brings about targeted further development of the overall printing process. Currently, this is being done primarily in the area of 3D printing, and here specifically for fusion layering and stereolithography. In addition, conventional printing processes are also being investigated for various applications such as security features and printed biosensors. In the Printing Fluids and Interfaces research group, printing processes are examined and further developed with regard to their suitability for processing special functional materials in order to integrate functionalities such as semiconductors, electroluminescence, photoelectric effect or electrical conductivity into printed products. To this end, the surfaces and fluids involved in the process are characterized, described and simulated.

There is a wide variety of projects worked on, ranging from special research areas of the DFG (German Research Foundation), over funding for small and medium-sized enterprises, to bilateral projects with industrial partners, or even research funding through scholarships. We would like to present some of the projects here, so that you can get an idea of our diverse research subjects.

Our research concept is to make a significant contribution to the understanding of printing processes. This allows on the one hand the further development of existing systems and processes and on the other hand the development of new innovative systems.

The research work is generally based on an interaction of theory, modeling, simulation and experiment. Systems and processes existing today are analyzed and their underlying relationships are explored. Theoretical considerations and experimental investigations are used to fundamentally describe the interrelationships through model building. Simulation then enables calculations and predictions.

Study and teaching

The lectures and tutorialsof the IDD are integrated into the master program of mechanical engineering. Students at the IDD mainly belong to the mechanical engineering discipline, but also to biology, medicine, physics, mechatronics, electrical engineering, computer science as well as paper engineering and industrial engineering. For the practical training of students, the IDD has a wide range of laboratory equipment and the most important printers are available several times for parallel work by several groups. Topics for master's and bachelor's theses are assigned internally or, if desired, together with industry. Interesting and informative excursions to printing press manufacturers, as well as to suppliers, the processing industry and thematically related companies, are regularly offered and carried out.

Equipment

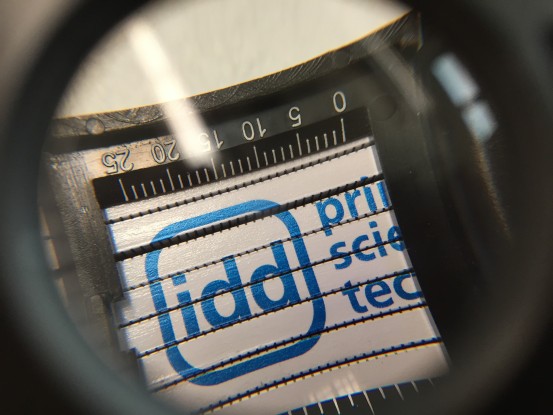

The laboratory equipment of the IDD is divided into several laboratories. The 3D printing labs have several printers using fused filament modeling, stereolithography and selective laser sintering techniques, as well as a wide variety of 3D scanners. The printers are each optimized for different special applications such as printing of high performance polymers, printing with multiple materials, the use of special extruders, etc. The newly established S1 bio lab combines a cell culture area and a bio printing area, allowing research work on 3D bio printing to be carried out optimally. The conventional printing lab has a three-level setup from printability devices with lowest substrate and fluid consumption over lab printing machines to industrial production machines. All common printing processes such as offset, gravure, screen, flexo, pad and inkjet printing as well as embossing processes are available. In the area of pre-treatment as well as post-treatment, a wide range of equipment such as corona and plasma systems as well as UV, IR, flash and hot air dryers and laser post-treatment are available for 3D as well as conventional printing processes. For the evaluation of graphic print products, as well as the quantification of optically readable biosensors, we have a color laboratory with precise laboratory measuring instruments and hand-held devices commonly used in practice (spectrophotometer, gloss and light measuring devices). We operate a climate laboratory, which controls humidity and temperature in the highest accuracy class, as well as reduces the particle load of the room air. In the haracterization laboratory, plastics, fluids, substrates, and printed products can be examined using optical microscopic, mechanical, electrical, and rheological measurement techniques.

Services: We do research for you

The research platform of the IDD can be used by interested companies within the framework of service contracts. Cooperation is possible from technical and/or economic consulting of companies, calculation, simulation, development contracts and printing tests, up to the support of an entire product development process.

Experiences in the cooperation with small and medium-sized enterprises are available, also by using public funding. Interdisciplinary industrial projects in cooperation with other research institutes under coordination of the IDD are possible.

Feasibility studies, for example on printability issues, are offered as a preliminary stage of industrial cooperation.

System development for customized printing and peripheral systems is also part of the IDD's service profile.

Full confidentiality is always guaranteed during all services and research.